Ecoflex Manufacturing

IBCs & Components

At Ecoflex, we have engineered our anti-static and ultra-violet (UV) light inhibiting IBCs, tanks, valves, and lids from the ground up to provide superior safety and performance.

Our products are built for the rigorous demands of various industries, ensuring the integrity of your materials and the safety of your operations.

IBC Tanks:

Advanced Protection from the Inside Out

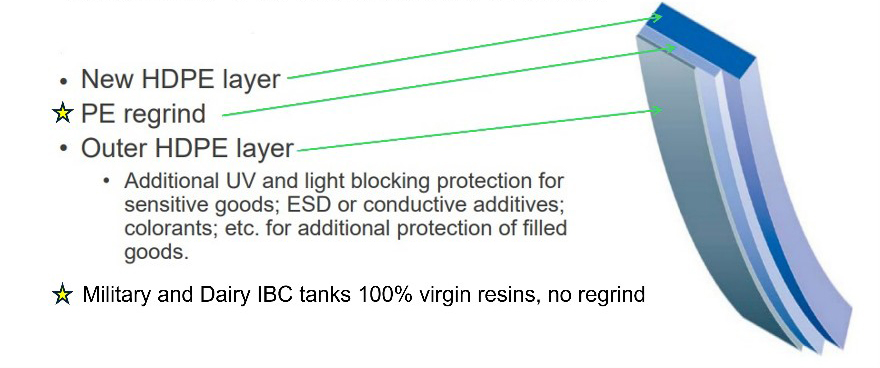

Our IBC tanks are crafted from high-density polyethylene (HDPE) resin using a multilayer construction.

This unique three-layer system provides:

- Static Resistance: The outer layer is specifically designed to dissipate static electricity, minimizing the

risk of discharge and protecting sensitive or flammable materials. - UV Light Protection: Each of the 3-layers

are UV-protective, guarding your contents from

light degradation and spoilage. - Material Purity: For military and dairy applications, our tanks are made with 100% virgin resins to ensure the highest level of purity.

Regardless of size or design, our IBCs are designed and tested to be leak proof and cost competitive.

We are proud to offer the dairy and pharmaceutical industries an anti-static IBC made with a special FDA approved Dairy (homopolymer) resin as a standard product.

Generally, our anti-static IBCs are produced with an FDA approved Household-Industrial-Chemical (HIC) copolymer resin.

Multilayer IBC tank Cross-section

Stainless Steel Cages:

Built for Durability

The strength of an IBC is determined by its tank and its protective cage. Ecoflex clients a choice in cages stainless steel for your specific needs. Since Ecoflex processes its cage components in-house, our clients receive the highest quality products.

Our stainless-steel cages are available in two grades:

- SAE 304 (UNS S30400, ASTM A276/A276M) Stainless Steel: A strong, reliable option with

excellent resistance to corrosion and fatigue. - SAF Duplex 2205 (UNS S32205, ASTM A276/A276M) Stainless Steel: This material offers superior corrosion resistance and strength, making it the ideal choice for demanding environments

like marine, high-chlorine, and biofuel applications..

The Ecoflex Difference: Duplex 2205 vs. 316L Stainless Steel

We chose Duplex 2205 over 316L stainless steel. While 316L is a strong and reliable option for general industrial use, Duplex 2205 offers superior corrosion resistance and strength, particularly in high-chloride environments. This makes Duplex 2205 the preferred choice for demanding applications like marine, high-chlorine, and biofuel.

Although 316L is easier to process and weld, our Duplex 2205 cages are specifically designed for applications requiring high strength and resistance to stress corrosion cracking, ensuring the integrity and longevity of your IBC.

Pallets:

Safety from the Ground Up

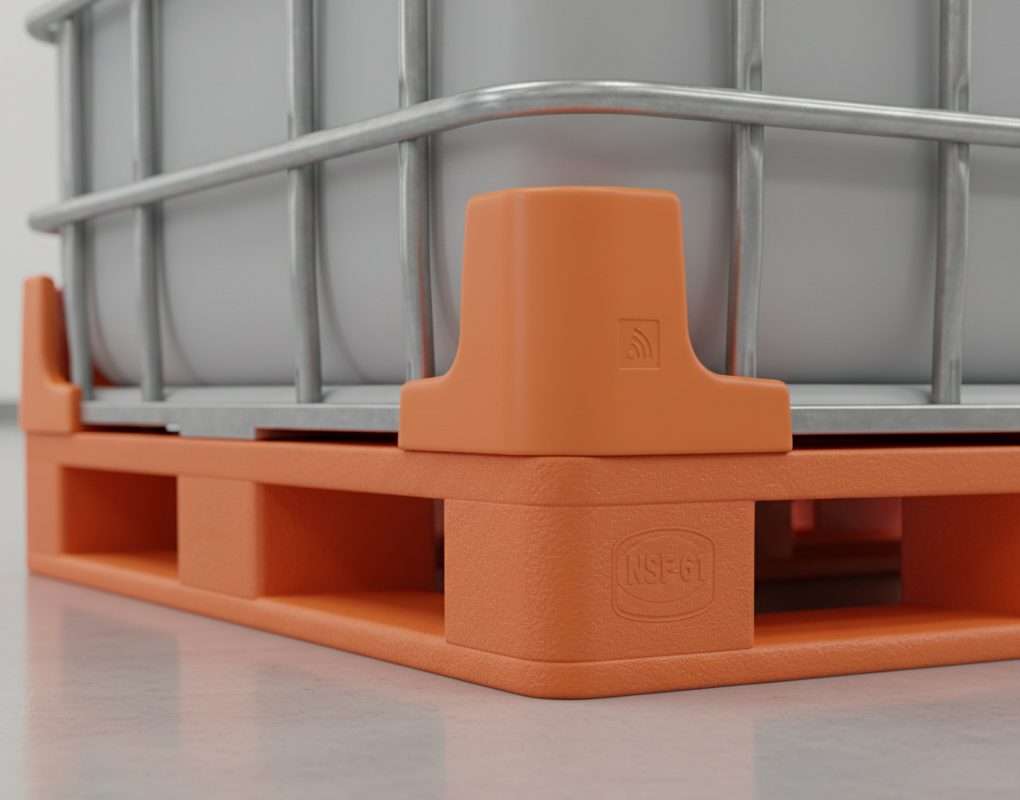

Our IBCs also feature a unique orange corner protector that provides extra puncture safety and signifies the container is anti-static.

Valves & Lids:

Secure and Simple

- Valves: Our quick-disconnect NPS valves (with ground wire) are pressure and static-tested. They come with an aluminum foil seal, a color-coded end cap and a handle that corresponds to the gasket type. Our valves are available with either a 2-inch (DN50) or 2.5-inch (DN65) discharge.

- Lids: We offer standard plain lids in 6-inch (DN 150) and 8-inch (DN 200) sizes. Like our valves, the lid color corresponds with the type of gasket or O-ring to ensure a proper fit.

Customization Options

Ecoflex offers a range of customization options to meet your specific industry needs, including specialized materials and certifications.

- Orange - "anti-static"

- Dark Green - MIL SPEC component with "NBR" gasket or O-ring

- Blue - "Dairy" Component with "NBR" gasket or O-ring

- Yellow- Component with "V-FKM" gasket or O-ring

- Violet - Component with "EPDM" gasket or O-ring

Compliance and Attributes

Our anti-static IBCs are designed for use across multiple industries and applications.

The following table provides a breakdown of our models and their key attributes.