Protecting Lives & Families

When a chemical fire breaks out, everyone nearby is at risk of inhaling deadly fumes. That’s why Ecoflex designs anti-static, UV-protected, and flame-retardant IBCs, because lives depend on it.

On November 20, 2017, a tragic IBC fire at Verla International Ltd. (credit: recordonline.com) highlighted the dangers of inside storage and usage of flammable liquids.

1.jpeg?width=828&height=816&name=IBC%20w-Plastic%20Pallet%20(1)1.jpeg)

When a chemical fire breaks out, everyone nearby is at risk of inhaling deadly fumes. That’s why Ecoflex designs anti-static, UV-protected, and flame-retardant IBCs, because lives depend on it.

On August 1, 2024, the EPA determined that “fluorinated” HDPE can contain banned per- and polyfluoroalkyl substances (PFAS). According to the ATSDR, PFAS can harm the heart, liver, reproductive, and renal systems.

Ecoflex IBCs are PFAS-free and Proposition 65 compliant.

Safety oversight is fragmented:

Ecoflex goes further, aligning with all three and exceeding minimum requirements.

Even the Rigid Intermediate Bulk Container Association (RIBCA-NA) has highlighted the safety benefits of anti-static IBCs.

But while competitors largely stayed silent, Ecoflex acted.

100% Recyclability Targets: Our clients receive recycling discounts up to 15% off future orders, based on purchasing volumes.

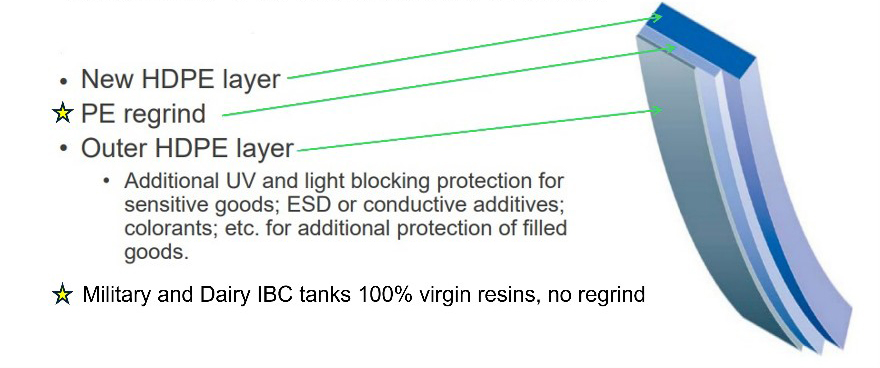

Recycled Content: Specific units may contain 25-40% recycled HDPE content. Ecoflex stainless steel cages and pallets are 99% recyclable.

Reuse Targets & Waste Reduction: Ecoflex's recycling target is 100% of our IBCs and 40% of our competitors IBCs annually.

Digital Labeling: Ecoflex IBC's labels provide reconditioning information.

** Ecoflex's IBCs designed for carrying foods, dairy, or pharmaceutical products are made with 100% new FDA approved plastic resins.

Ecoflex prioritizes environmentally responsible practices, reducing environmental impact through efficient resource use and waste reduction and disposal.

Every product undergoes strict quality assurance protocols to guarantee reliability and performance that exceed industry standards.

100% of our products are anti-static. We utilize cutting-edge technology, FDA compliant plastic resins, and rigorous quality control to ensure every product meets the highest standards.

Our manufacturing process is designed for efficiency and durability, delivering defect-free IBCs, IBC tanks, valves, and lids.

Our reconditioning process extends the life of components through meticulous inspection, cleaning, and refurbishment. This sustainable approach reduces waste and provides cost-effective alternatives without compromising quality or performance.

Our skilled professionals are committed to innovation and customer satisfaction, ensuring every order is handled with expertise and care.

At Ecoflex, our dedication to safety is backed by rigorous testing and full compliance with both global and regional standards. This commitment ensures our containers not only meet but exceed the expectations of our customers and the industry.

Ecoflex products contain no Per- and Polyfluoroalkyl Substances (PFAS), also known as "forever chemicals," which have been linked to significant health risks. We also do not use Ethylene Vinyl Alcohol (EVOH) high-barrier material, choosing instead to focus on materials with a proven safety record.

Our strict adherence to these standards is why we proudly comply with California's Proposition 65 (Safe Drinking Water and Toxic Enforcement Act of 1986). This law requires businesses to provide warnings about significant exposure to harmful chemicals and prohibits the discharge of these chemicals into drinking water sources—a principle that is fundamental to our manufacturing process and our promise to you.